2600W 230mm(9'') Angle Grinder

PAE26-H-EU

(5.0)

(5.0) |  |  |

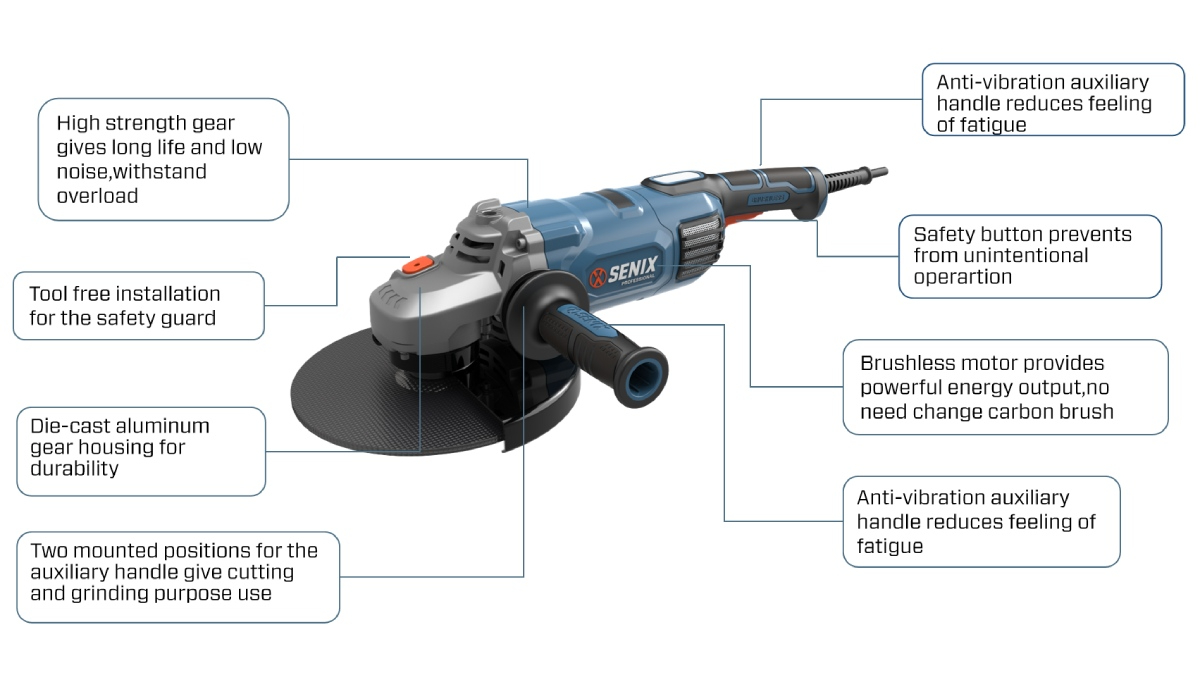

KEY FEATURES

High Strength Gear – provides long life and low noise, resists overload

Tool-Free Safety Guard – quick and easy installation

Die-Cast Aluminum Gear Housing – durable and robust construction

Anti-Vibration Auxiliary Handle – minimizes user fatigue during prolonged use

Safety Button – prevents accidental start-ups for safer operation

Brushless Motor – delivers powerful performance with no carbon brush maintenance

Large Cutting Diameter – 230mm (9") for fast and efficient material removal

TECHNICAL PARAMETERS

Model | PAE26-H-EU |

Voltage | 220V~240V/50-60Hz |

Motor Type | Brushless |

Rated Power | 2600W |

Cutting Diameter | 230mm(9 inch) |

No-Load Speed | 5700RPM |

Thread of Output Shaft | M14 |

Product weight | 6 kg |

Recommended Operating Temperature | -20℃ ~ 40℃ |

Recommended Storage Temperature | -20℃ ~ 70℃ |

Product dimensions | 560*110*141mm |

Color box Size | 565*135*165mm |

SUPPORT

Product Overview

The SENIX 2600W 230mm Angle Grinder is designed for demanding applications in workshops, construction sites, and professional environments. Powered by a 2600W brushless motor, it achieves a no-load speed of 5700RPM, delivering robust cutting and grinding performance with minimal maintenance due to its brushless design.

Durability is built into every aspect of this tool. The high-strength gear ensures long life, low noise, and overload resistance, while the die-cast aluminum gear housing provides structural integrity and protection for internal components. Tool-free installation of the safety guard adds convenience and improves operational efficiency.

User comfort is a priority with the SENIX 2600W. The anti-vibration auxiliary handle reduces fatigue during extended use, and the two handle mounting positions allow flexibility for both cutting and grinding tasks. A safety button prevents unintentional operation, enhancing worksite safety. The ergonomic design, combined with the large 230mm disc diameter, enables fast material removal while maintaining precision.

Lightweight and well-balanced at 6kg, the grinder offers excellent maneuverability despite its powerful motor. Its combination of power, comfort, and durability makes it ideal for professional craftsmen and heavy-duty applications.

Usage Scenarios

Construction Sites: AC angle grinders are widely used on construction sites for cutting, grinding, and polishing metal, significantly improving work efficiency.

Renovation Projects: During renovation work, AC angle grinders are essential for cutting, grinding, and polishing metal materials, helping ensure high-quality finishes.

Metal Fabrication Workshops: A staple tool for metalworking professionals, AC angle grinders are commonly used for various operations including metal cutting, grinding, and polishing.

Other Metalworking Applications: Ideal for tasks such as automotive repair, pipeline maintenance, and any other situation requiring efficient metal cutting, grinding, or polishing.

Unrecommended Conditions

Cutting and Grinding Non-Metal Materials: AC angle grinders are primarily designed for metalworking. They are not recommended for use on non-metal materials such as wood or plastic, as this may lead to tool damage or suboptimal results.

Cutting Overly Thick Metal: While capable of cutting metal, AC angle grinders are not suitable for cutting extremely thick metal materials (e.g., hardened metal exceeding 20 mm in thickness), due to reduced performance and increased safety risks.

Warranty Information

We offer a comprehensive warranty policy tailored to the specific requirements of different countries and regions. Our warranty coverage is designed to ensure customer satisfaction and product reliability across all markets. For detailed information regarding the terms, duration, and service procedures applicable in your location, please contact us directly. Our team will provide you with a complete warranty illustration and support as needed.

FREQUENTLY ASKED QUESTIONS

- Q1: What materials can this grinder handle?