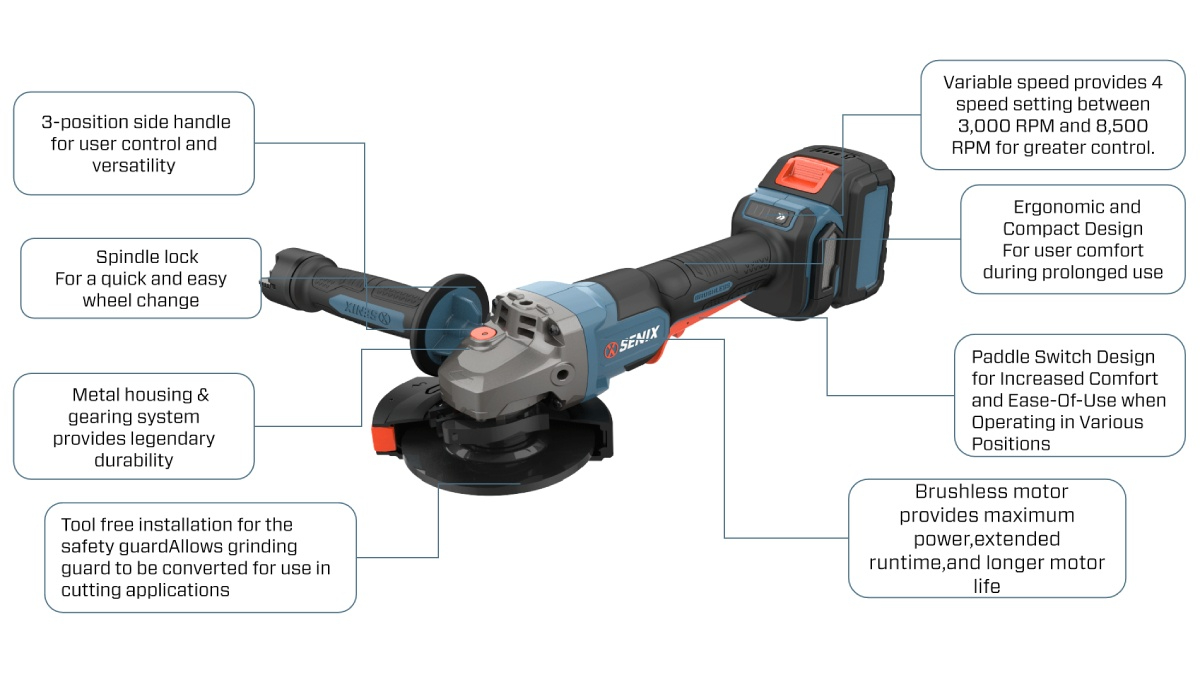

20V Brushless 125mm(5'') Paddle Switch Angle Grinder

PAX2-M2-EU

(5.0)

(5.0)KEY FEATURES

3-Position Side Handle – Enhances user control and application versatility

Spindle Lock – Enables quick and easy wheel changes

Durable Metal Housing & Gearing System – Delivers long-lasting performance

Tool-Free Safety Guard Installation – Easily converts between grinding and cutting

Variable Speed Control – 4 settings from 3,000 to 8,500 RPM for precision

Ergonomic & Compact Design – Provides comfort during extended use

Paddle Switch Design – Offers better comfort and control in various working positions

Brushless Motor Technology – Delivers maximum power, longer runtime, and extended motor life

TECHNICAL PARAMETERS

Model | PAX2-M2-EU |

Voltage | 20V Max DC |

Motor type | Brushless |

No Load Speed | 3000/4500/6000/8500RPM |

Max. Disc Diameter | 125mm(5 inch) |

Spindle Thread | M14 |

Hole Dia. of Wheel | Φ22.23mm |

Work Amount (approx.) | Cutting 1.6m long& 16mm depth Concrete plate with 5Ah battery |

Machine Weight (Tool Only) | 1.9 kg |

Recommended Operating Temperature | -15°C ~ 40°C |

Recommended Storage Temperature | -20°C ~ 70°C |

Certification | CE |

Machine Size | 311*155*130mm |

Color Box Size | 338x188x123mm |

SUPPORT

Product Overview

The SENIX 20V Brushless 5" Angle Grinder emphasizes cordless grinding and cutting with professional-grade power and versatility. Designed for demanding tasks, its brushless motor delivers maximum efficiency, extended runtime, and superior durability—ideal for cutting, grinding, and surface preparation. Weighing just 1.9 kg, this compact tool minimizes fatigue during prolonged use, while the 4-position variable speed (3,000–8,500 RPM) ensures precision control across materials like concrete, metal, or tile. Performance-tested to cut 1.6m of 16mm concrete per 5Ah battery charge, this grinder excels in construction, metalworking, and DIY projects. Its ergonomic design, certified for safety (CE), operates smoothly in temperatures from -15°C to 40°C. Whether tackling rebar, tile, or masonry, the SENIX 20V Brushless Grinder combines cordless freedom with uncompromising power—all in a lightweight, user-centric package.

Usage Scenarios

Construction Sites: Angle grinders are used for cutting, grinding, and polishing metal, improving work efficiency.

Renovation Projects: During renovations, angle grinders are used for cutting, grinding, and polishing metal materials to ensure quality results.

Metal Fabrication Workshops: Commonly used by metalworkers for cutting, grinding, and polishing metal components.

Other Metalworking Scenarios: Such as auto repair, pipeline maintenance, and more, where metal cutting and grinding are needed.Unrecommended Conditions

Cutting Overly Thick Metal Materials: While angle grinders can cut metal, they are not suitable for very thick metals (e.g., hardened metal over 20mm thick). The cutting effect may be poor, and there are potential safety risks.

Warranty Information

We offer a comprehensive warranty policy tailored to the specific requirements of different countries and regions. Our warranty coverage is designed to ensure customer satisfaction and product reliability across all markets. For detailed information regarding the terms, duration, and service procedures applicable in your location, please contact us directly. Our team will provide you with a complete warranty illustration and support as needed.

FREQUENTLY ASKED QUESTIONS

Q1: What battery system does this grinder use

A: It's part of the SENIX X2 20V platform (compatible with SENIX 20V 2.0Ah/4.0Ah/5.0Ah batteries).

Q2: Can it handle cutting metal and concrete?

A: Yes! With a max 125mm disc, it cuts 16 mm-deep concrete (tested) and works with metal/tile discs.

Q3: Is the safety guard adjustable?

A: Absolutely—tool-free guard installation lets you switch between grinding and cutting modes in seconds.

Q4: Why choose brushless motor technology

A: Longer motor life, 30% more runtime vs. brushed motors, and higher power efficiency.

Q5: What's included in the box?

A: Grinder, 3-position side handle, safety guard, user manual, battery, and charger.

Q6: Can I use it in cold conditions?

A: Yes! Operates reliably from -15°C to 40°C.

Q7: How do I change discs?

A: Use the spindle lock to secure the arbor, then swap discs via the M14 thread—no tools needed.