20V Brushless 690Bar Grease Gun

GGX2-M1-EU

(5.0)

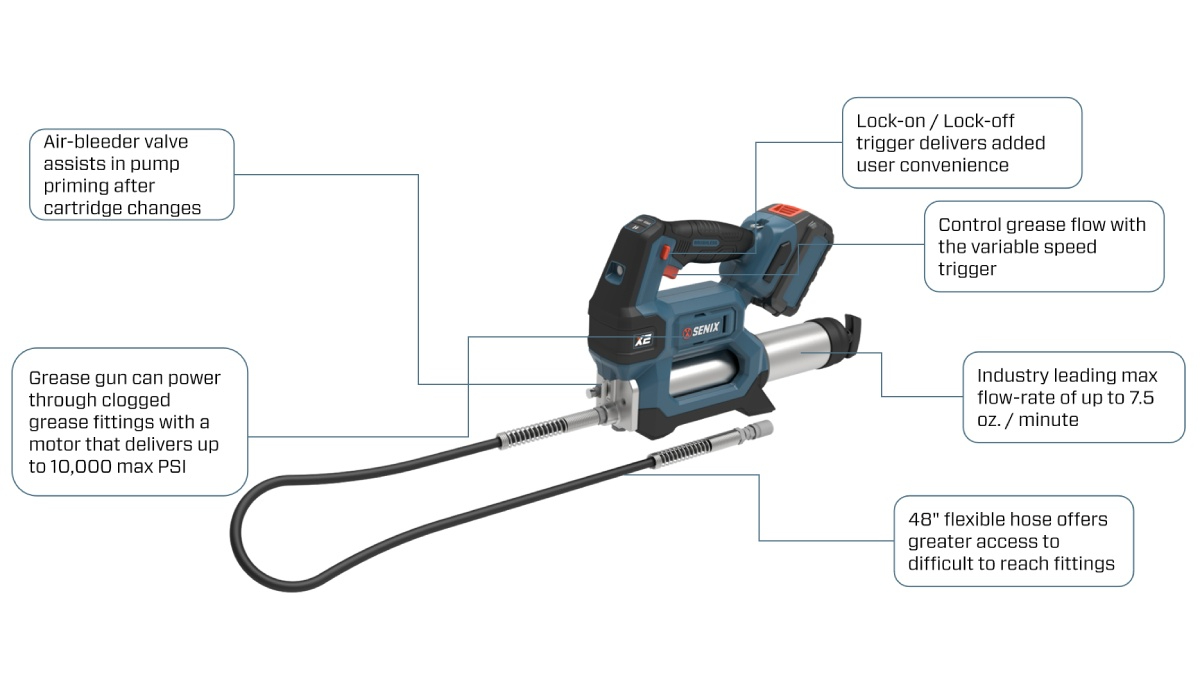

(5.0)The SENIX 20V Brushless Grease Gun delivers 10,000 PSI pressure and up to 10 oz/min flow rate, making it ideal for industrial-grade lubrication. Its pre-set grease dial, air bleeder valve, and 48" flexible hose ensure precision, ease, and efficiency on every job.

KEY FEATURES

High Pressure Performance – Delivers industry-leading 10,000 PSI max operating pressure for demanding lubrication tasks

Adjustable Flow Rate – Pre-set grease counter dial allows precision delivery and reduced waste

Quick Priming – Integrated air bleeder valve ensures fast and easy priming to avoid downtime

Lock-On / Lock-Off Trigger – Provides continuous operation and added user control

Extended Reach Hose – 48" flexible hose easily accesses hard-to-reach fittings

Brushless Motor Efficiency – Ensures longer motor life, maximum power, and superior battery performance

Comfort-Oriented Design – Balanced structure and ergonomic grip reduce fatigue during long use

Tool-Free Cartridge Replacement – Simplifies reloads, saving time on the job

Battery Interchangeability – Compatible with all SENIX 20V Max DC lithium-ion batteries

TECHNICAL PARAMETERS

Model | GGX2-M1-EU |

Voltage | 20V Max DC |

Motor type | Brushless |

Max pressure | high: 690bar low: 345bar |

Flow rate | low: 103.5ml/min high: 221ml/min |

Grease Capacity | 455g (16 oz) Bulk 410g Cartridge |

Hose length | 122cm(48 inch) |

Work Amount | 10205.8g (370 oz) per 5Ah battery |

Recommended Operating Temperature | -18℃ ~ 52℃ |

Recommended Storage Temperature | -20℃ ~ 70℃ |

Certification | CE |

Machine Weight (Tool Only) | 3.6 kg |

Machine Size | 238*385*98mm |

Color Box Size | 569*264*135mm |

SUPPORT

Product Overview

The SENIX 20V Brushless 690Bar Grease Gun is engineered to meet the toughest lubrication demands in industrial, automotive, and agricultural settings. This cordless grease gun delivers unmatched performance and efficiency with a best-in-class max pressure of 10,000 PSI and a max flow rate of 10 oz/min. It's equipped with a pre-set grease counter dial, offering precise control over the amount dispensed—ideal for professionals who demand consistent and measured output.

Designed for comfort and convenience, the tool features a lock-on/lock-off trigger, a 48-inch flexible hose for improved access, and an air bleeder valve that primes the pump quickly, minimizing downtime. The brushless motor ensures maximum power with extended runtime and durability. Its versatile loading system accommodates both 455g bulk grease and 410g cartridges.

Usage Scenarios

Automotive Maintenance and Repair:

Chassis Lubrication: Used for lubricating vehicle undercarriage parts like suspension systems and steering mechanisms.

Bearing Lubrication: Ideal for wheel bearings and other rotating parts of the vehicle, ensuring smooth operation.

Industrial Manufacturing:

Production Line Equipment: Utilized for lubrication of machinery and conveyor belts in manufacturing plants.

Heavy Machinery: Suitable for greasing large industrial machines like stamping presses and injection molding machines.

Construction Sites:

Construction Machinery: Essential for lubricating joints and bearings in heavy-duty machinery such as excavators, bulldozers, and cranes.

Concrete Equipment: Great for lubricating components of concrete pump trucks and mixer trucks.

DIY & Household Use:

Home Machinery: Used for greasing home machinery like lawnmowers and power tools.

Bicycles and Motorcycles: Perfect for lubricating chains and bearings on bicycles and motorcycles.

Unrecommended Conditions

Precision Equipment: Using a grease gun for equipment requiring precise lubrication can result in over-lubrication, which may impair the device's performance.

Small Parts: For very small mechanical components, manual lubrication may be more suitable to avoid excessive grease application.

Underwater or Moist Environments: Standard grease guns are not designed for underwater or wet conditions. Waterproof lubrication equipment is recommended in such environments.

High-Speed Rotating Equipment: For high-speed bearings or parts, standard grease may not provide sufficient lubrication. Special high-speed lubricants and equipment should be used instead.

Automated Lubrication Needs: Grease guns are not suitable for systems requiring precise and automated grease control, such as in automated production lines. An automatic lubrication system is needed for these scenarios.

Warranty Information

We offer a comprehensive warranty policy tailored to the specific requirements of different countries and regions. Our warranty coverage is designed to ensure customer satisfaction and product reliability across all markets. For detailed information regarding the terms, duration, and service procedures applicable in your location, please get in touch with us directly. Our team will provide you with a complete warranty illustration and support as needed.

FREQUENTLY ASKED QUESTIONS

- Q1: What type of grease cartridges does this tool support?

A: It supports standard 410g cartridges and can also be filled with 455g bulk grease directly.

Q2: How do I prime the grease gun if it loses prime?

A: Simply use the built-in air bleeder valve to release trapped air and restore proper flow.

Q3: Can it handle heavy-duty machinery or farm equipment?

A: Yes. With up to 10,000 PSI and a 48" hose, it's ideal for high-pressure applications on industrial or agricultural equipment.

Q4: What is the flow rate, and can it be adjusted?

A: The flow rate is up to 221ml/min on high mode and 103.5ml/min on low. Flow is controlled by the lock-on/lock-off trigger and pre-set dial.

Q5: How many cartridges can I use?

A: The tool can dispense up to 10,205g (370 oz) of grease, which translates to over 24 full cartridges per full 5Ah battery charge.

Q6: Is it compatible with other SENIX 20V batteries?

A: Yes, it is compatible with all SENIX 20V lithium-ion battery packs.