1010W 125mm(5'') Angle Grinder

PAE10.1-M1-EU

(5.0)

(5.0) |  |  |  |

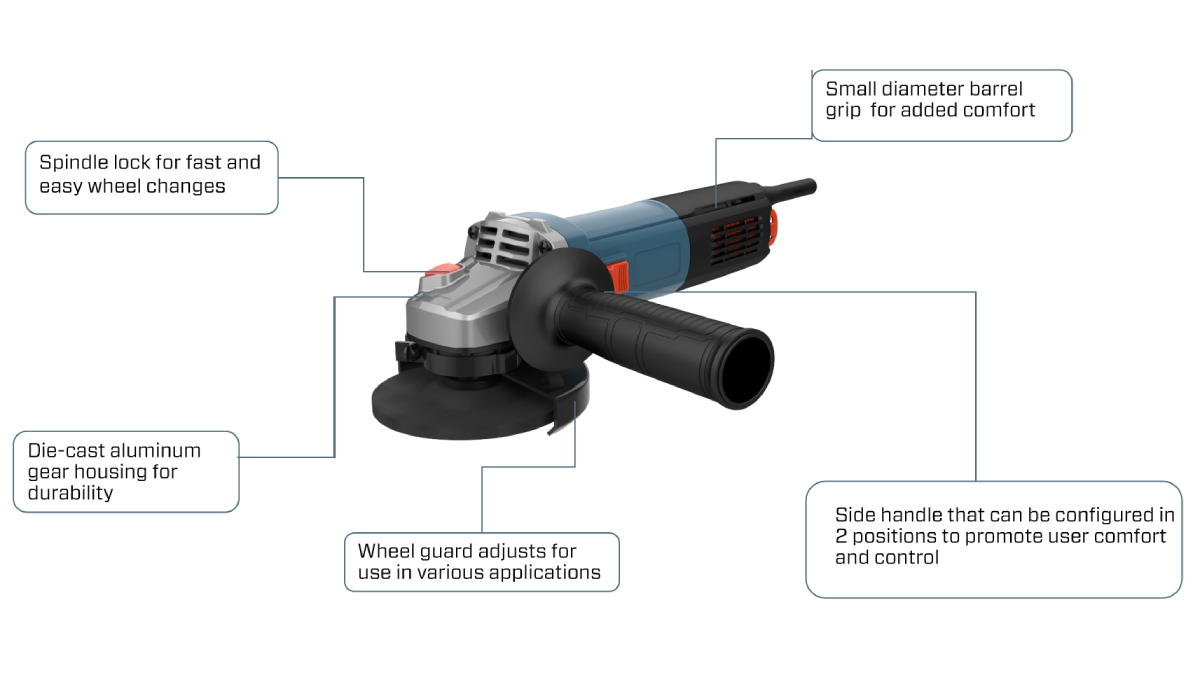

KEY FEATURES

Spindle Lock – fast and easy wheel changes

Small Diameter Barrel Grip – added comfort and control

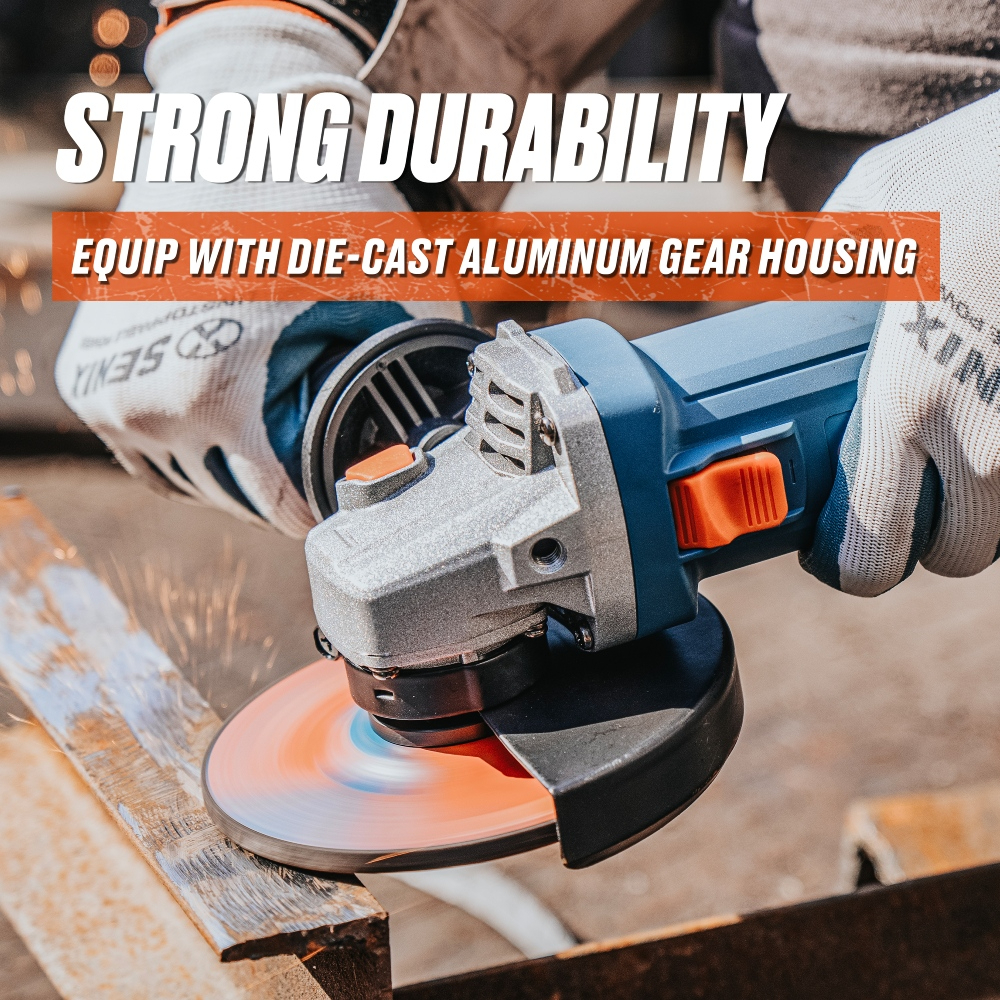

Die-Cast Aluminum Gear Housing – durable and long-lasting

Wheel Guard – adjusts for use in various applications

Side Handle – configurable in 2 positions for enhanced comfort and control

High-Speed Motor – 1010W with 11,000 RPM for efficient cutting and grinding

TECHNICAL PARAMETERS

Model | PAE10.1-M1-EU | ACCESSORIES |

Voltage | 220-240V/50-60Hz | 1. All-plastic auxiliary handle 2. Sanding wheel cover 3. Spanner 4. Spare carbon brushes 5. Grinding disc 6. Cutting disc |

Power | 1010W | |

No-Load Speed | 11000RPM | |

Disc Size | 125mm | |

Disc Inner | 22.2mm | |

Side Handle Screw | M10 | |

Certification | SAA |

SUPPORT

Product Overview

The SENIX 1010W 125mm (5") Angle Grinder is built to handle a wide variety of cutting, grinding, and sanding applications with efficiency and precision. Powered by a robust 1010W motor and capable of reaching 11,000 RPM, this grinder is perfect for both professional workshops and DIY enthusiasts.

Its spindle lock allows for quick and secure wheel changes, reducing downtime during projects. The small-diameter barrel grip ensures comfort and control, while the die-cast aluminum gear housing offers durability and stability even during intensive use. The adjustable wheel guard enhances safety and allows the grinder to be adapted for various tasks, while the side handle can be mounted in two positions to suit both left- and right-handed operators or different working angles.

Included accessories, such as the all-plastic auxiliary handle, sanding wheel cover, spanner, spare carbon brushes, grinding disc, and cutting disc, ensure you are ready to tackle multiple tasks immediately. The 125mm disc diameter and 22.2mm inner bore provide compatibility with a wide range of grinding and cutting wheels.

Compact and lightweight at just over 2 kg, the SENIX 1010W Angle Grinder is easy to maneuver, yet powerful enough for heavy-duty applications. Its thoughtful design, safety features, and accessory kit make it an indispensable tool for anyone seeking reliability, versatility, and precision in one compact package.

Usage Scenarios

Construction Sites: AC angle grinders are widely used on construction sites for cutting, grinding, and polishing metal, significantly improving work efficiency.

Renovation Projects: During renovation work, AC angle grinders are essential for cutting, grinding, and polishing metal materials, helping ensure high-quality finishes.

Metal Fabrication Workshops: A staple tool for metalworking professionals, AC angle grinders are commonly used for various operations including metal cutting, grinding, and polishing.

Other Metalworking Applications: Ideal for tasks such as automotive repair, pipeline maintenance, and any other situation requiring efficient metal cutting, grinding, or polishing.

Unrecommended Conditions

Cutting and Grinding Non-Metal Materials: AC angle grinders are primarily designed for metalworking. They are not recommended for use on non-metal materials such as wood or plastic, as this may lead to tool damage or suboptimal results.

Cutting Overly Thick Metal: While capable of cutting metal, AC angle grinders are not suitable for cutting extremely thick metal materials (e.g., hardened metal exceeding 20 mm in thickness), due to reduced performance and increased safety risks.

Warranty Information

We offer a comprehensive warranty policy tailored to the specific requirements of different countries and regions. Our warranty coverage is designed to ensure customer satisfaction and product reliability across all markets. For detailed information regarding the terms, duration, and service procedures applicable in your location, please contact us directly. Our team will provide you with a complete warranty illustration and support as needed.

FREQUENTLY ASKED QUESTIONS

- Q1: Can I use this grinder for both cutting metal and masonry?

A: Yes, the SENIX 1010W supports a variety of discs suitable for metal, masonry, and other materials.

Q2: How do I change the grinding or cutting disc?

A: Press the spindle lock to hold the disc in place, then use the included spanner to loosen or tighten the disc.

Q3: Can the side handle be mounted on both sides?

A: Yes, the side handle is reversible and can be mounted in two positions for left- or right-handed operation.

Q4: Is this grinder suitable for long-term use?

A: Yes, the die-cast aluminum housing and ergonomic design reduce fatigue and provide durability for extended sessions.

Q5: Are replacement parts like carbon brushes easy to replace?

A: Yes, spare carbon brushes are included and can be replaced externally without disassembling the grinder.

Q6: What safety precautions should I follow?

A: Always wear protective gear, ensure the wheel guard is in place, and use the grinder with proper discs rated for the material.

Q7: Can I adjust the wheel guard for different cutting angles?

A: Yes, the wheel guard is adjustable to provide safe operation for multiple applications.